|

Key Features:

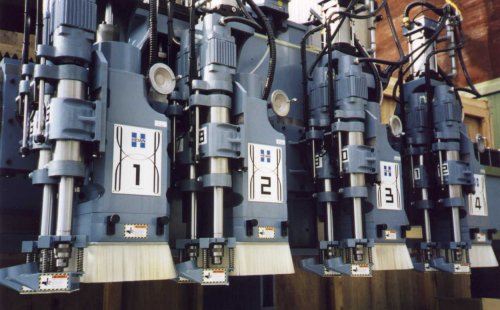

THE HEIAN SPINDLE

Heian's patented spindle motors offer unequalled precision,

wide-ranging power bands, and durability.

|

|

4.5, 5.5, 7.5, 11 & 12kW or higher constant power motors.

|

|

|

High efficiency inverter and electric spindle

brake.

|

|

|

18,000 rpm, 20,000 rpm, 24,000 rpm and 30,000 rpm

options

|

|

|

Three angular contact ball bearings for heavy

cutting.

|

|

|

Special heat treated, ground and balanced spindle

rotor.

|

|

|

Air/oil micro-mist spindle lubrication.

|

|

|

Handwheel fine adjustment.

|

|

|

Nut and collet, or tool holder options: BT30, 35

and 40 & HSK63.

|

RIGID MACHINE CONSTRUCTION

|

|

Heavy duty cast iron base, table and spindle

mounting components.

|

|

|

Engineered structural steel weldments; stress

relieved and normalised.

|

|

|

Precision large-scale CNC machining, accurate

assembly and alignment.

|

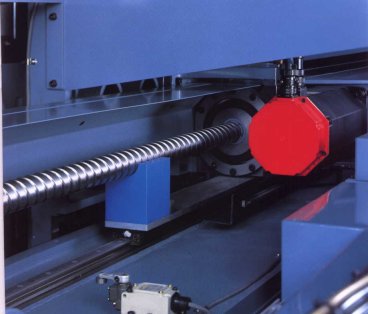

HIGH PRECISION BALLSCREWS AND GUIDEWAYS

|

|

Precision ground chrome-molebdenum

steel.

|

|

|

Extra large diameter.

|

|

|

Patented "anti-backlash" ballscrew support system.

|

|

|

Hardened, round and grinned rectangular

guideways.

|

|

|

Tank track type precision roller bearings.

|

|

|

Automatic oil lubrication.

|

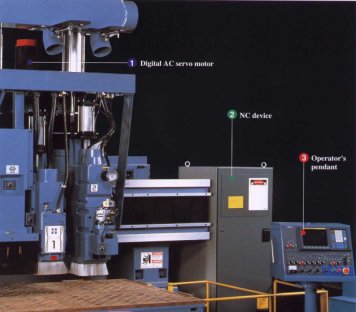

HEIAN-FANUC CNC CONTROL AND DRIVE

PACKAGE

|

|

Heian-Fanuc series 18iM, 21iM, 15iM and the xx0iM

dual NC/PC advanced digital computer controls. Optional Windows interface.

|

|

|

Movable remote operator's pendant.

|

|

|

Low maintenance Fanuc digital AC servo drives.

|

|

|

Linear encoder option.

|

CENTRAL LUBRICATION

|

|

Air-oil micro-mist spindle bearing lubrication

(since 1966).

|

|

|

Micro-mist cools and lubricates the spindle bearings.

|

|

|

Guideways and roller bearings are automatically

lubricated in preset intervals during machine operation.

|

|

|

Oil level and pressure alarms protect machine

from wear and damage.

|

|